Many times we are asked if it is possible to collect data from a device and transfer it directly into a Quality Window application… the quick answer is yes. Collecting data this way is ideal because it can greatly increase the accuracy of the data as well as decrease the time and effort. It also is very useful if a product is subject to some regulatory requirement.

A good example of the benefits was a customer that was required to take 10 individual samples every half hour and record each weight in Quality Window. This required over 80 keystrokes, if there were no corrections. It was a very time consuming process. By capturing the data directly from the device and placing it in the right fields in the Quality Window application, it made a tedious process very efficient and freed the person up for other duties. It also allowed for the tracking of individual weights as well as generating an average and range value through the use of calculated variables in the Quality Window Application.

Typically this would interface to devices like weight scales or calliper gages but just about any device with an RS232 output can be captured using our QWRS232 utility program included with Quality Window. Computers today normally do not come with RS232 ports but there are USB to RS232 converters to overcome this issue.

To accomplish the task you need to have the manual for the device that talks about the interface settings as well as the “right” cable to accomplish the task. I mentioned the “right” cable because when there is a problem getting the communication going between the device and Quality Window it is generally tracked back to the wrong cable.

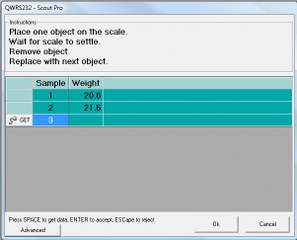

The Quality Window product includes the QWRS232 interface utility and there are two components. First the QWRS232Setup utility used to create and maintain RS232 configurations. The Help file that is included with the QWRS232Setup utility contains the necessary information in detail to make the interface work as you want it to. The second is the QWRS232 interface utility that will collect the data from the device and pass it to the Quality Window application.

Next you need to determine how many samples you wish to capture from the device as well as field sizes and decimal places along with a Minimum and Maximum value – this is to help prevent incorrect data from being captured. Again the Help file with the QWRS232Setup utility can guide you through the process.

You also have to understand the interface opportunities that are available in Quality Window. In the case of collecting data through the QWRS232 utility, I would suggest the “Execute Batch File when the A (add data) key is pressed. This is found in the QWAdmin – Applications – General screen. If you identify a Batch file (text file with list of commands to be performed) in this application setting Quality Window will run this process as soon as the A-add key is pressed but before the Add data screen appears.

Here is a quick visual overview of the process with comments using a scale interface example that comes with Quality Window called Scale Interface Example and it can be found in the QW Sample Applications\Weight Example directory.

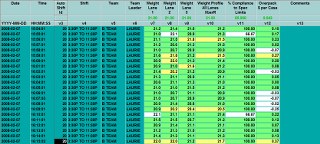

I started Quality Window 5 and selected the Scale Interface Example. The Logsheet screen will be displayed. NOTE: You must understand that for this example there is a scale connected and it is configured to accept data from the scale. If you attempt this with our Example application you would also have a scale connected and configured for this application.

Next the A-add data key is pressed. Normally the Add data screen would be displayed but the configuration settings for this Quality Window application tells Quality Window to run the QWRS232 scale interface utility to accept data form the scale.

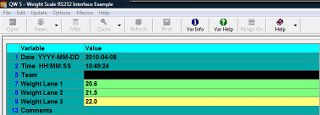

The data is captured directly from the scale and placed into the corresponding fields in the Quality Window Application. This greatly increases the integrity of the data and speed up the collection process.

If the fields in the Quality Window application are defined as Protected then the data from the scale cannot be changed once received by the Quality Window Application. These are key points for recording data for regulated brands like pharmaceuticals, and food products.

Additional Settings in the QWRS232 interface to consider are the setting of minimum/maximum values along with Auto Save once the scale has stabilized to increase the speed at which samples are taken.

Once the collection of data from the scale is completed the Add data screen appears and the Weight fields are filled with the data collected from the scale. At this point you can add additional information such as who performed the test or add comments. Once the data is saved (F10) the Summary screen (Rule Violations) may appear if any violations were detected.

Additional fields were added to this application to provide an average of the samples as well as a Compliance to Spec and Over/Under pack calculations. These types of fields add value and different ways to look at the data at no additional cost in terms of effort.

The QWRS232 interface capability is just one example of how to interface to devices and systems can greatly benefit your use of data in all areas of your operations.

See the QWRS232 Administration Guide for technical information on using QWRS232.